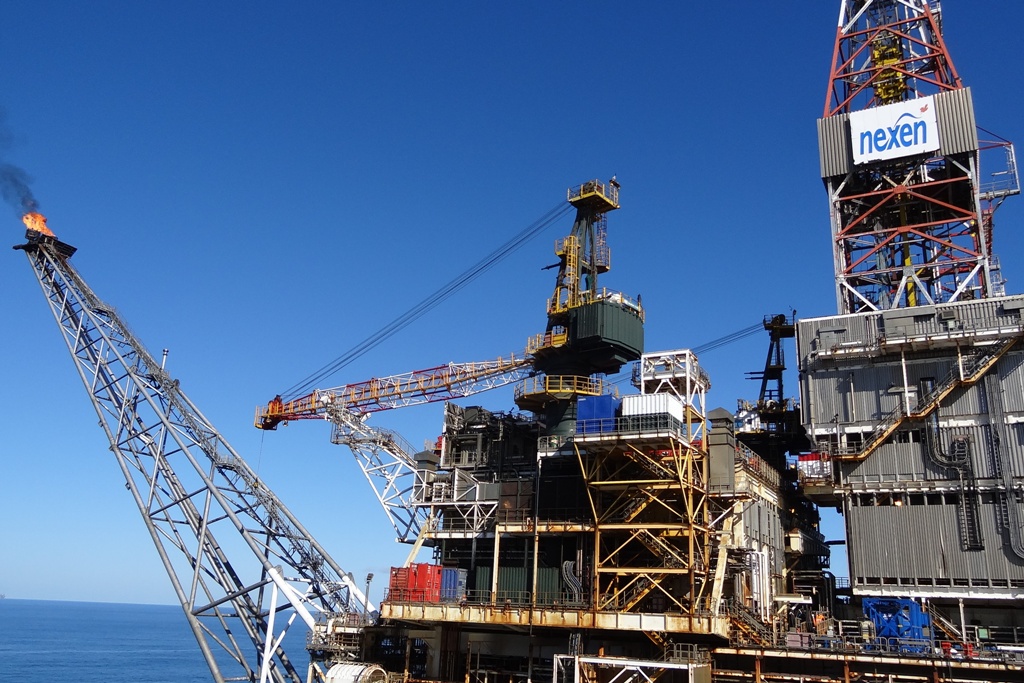

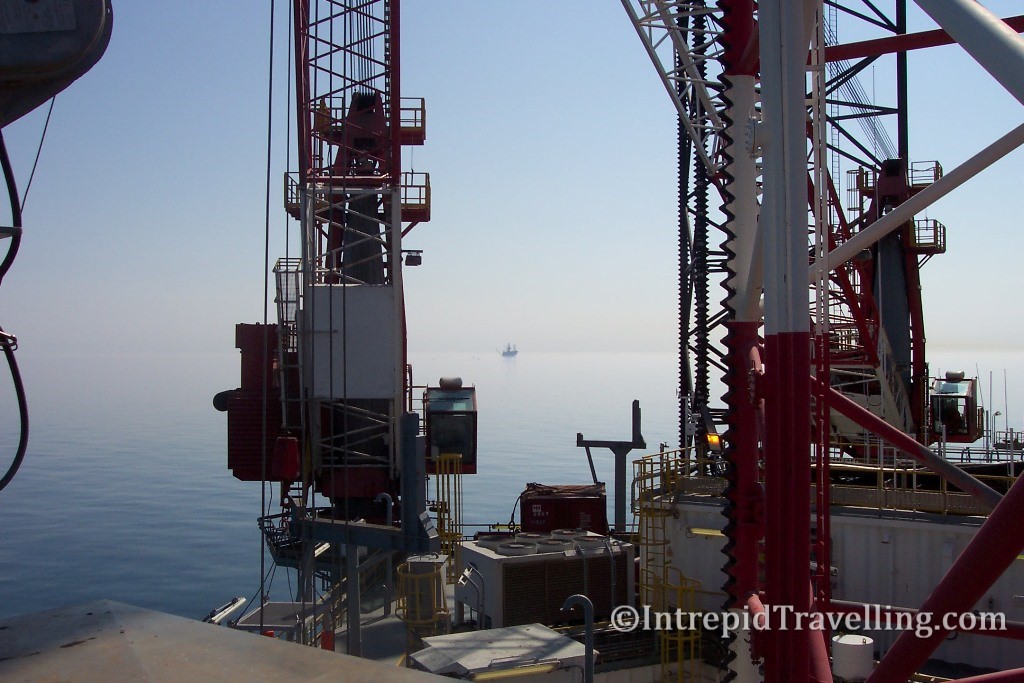

When I first arrived offshore I was in awe of where I was and what I was seeing, the scale of operations/machinery, the logistics involved and disbelief at what they were achieving; I was inspired to learn more! On a clear day/night in the middle of the North Sea you can count anywhere up to 20 other Rigs or platforms on the horizon; the Central North Sea Grabben is rich in Hydrocarbons and I would learn it’s a complicated process to get them to the markets. However, like any new endeavour there are times when you feel quite intimidated too, but this fades as you get up to speed.

A drilling rig is a complicated assortment of equipment which is fundamentally the same whether you’re talking about an onshore drilling rig or a super modern drillship. What does often change is the scale and cost of the operations.

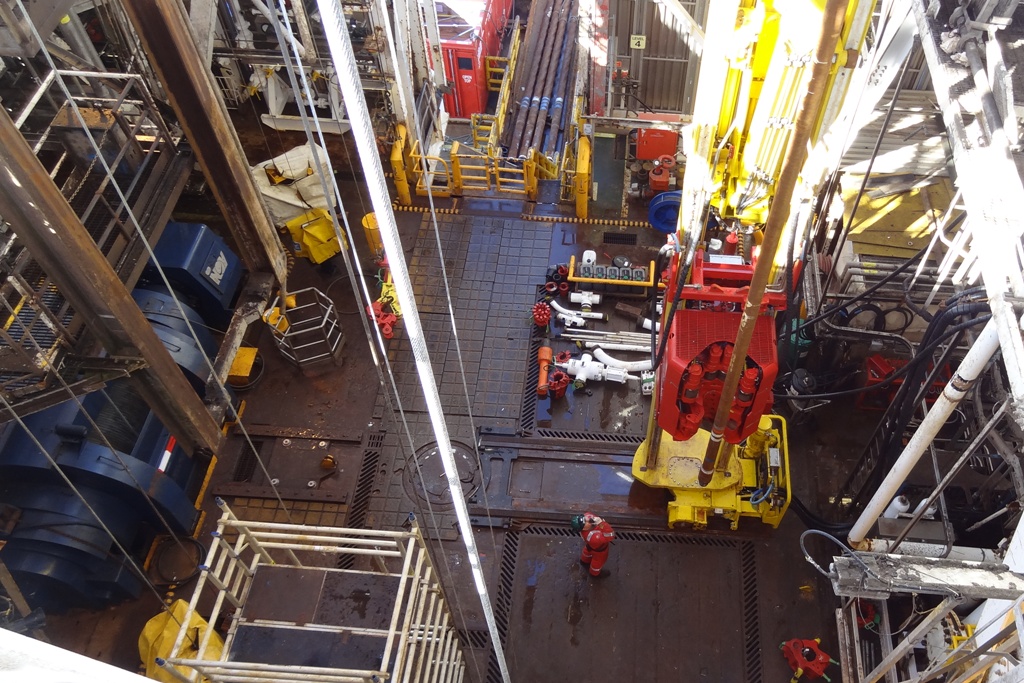

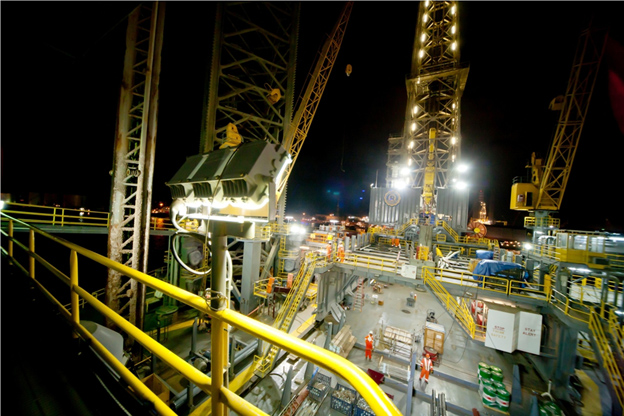

Below is a typical canter-lever deck where anything such as drill pipe and casing can be stored and managed. Deck space is at a premium on offshore drilling rigs so logistics plays an important role in keeping operations moving along efficiently. Work areas are kept clean and tidy with evacuation paths clearly marked and clear at all times.

The major pieces of equipment which make up the drilling system are listed below;

- Doghouse - The hub of operations is the Doghouse, or the drillers shack. This is where the Driller and the people responsible for the safe and efficient drilling of the well work. Communication critical to the operation flows through this room and if anything goes wrong with the well the Blowout Preventers (BOPs) are activated from here

- Cranes – All offshore installations need several cranes to bring on supplies and backload equipment to the supply vessels that regularly run between the nearest port and the rig or platform.

- Cantilever and Drilling Package – On a jackup drilling rig, the entire drilling derrick and drilling package can slide in and out to position itself overboard during operations and back onboard during a rig move.

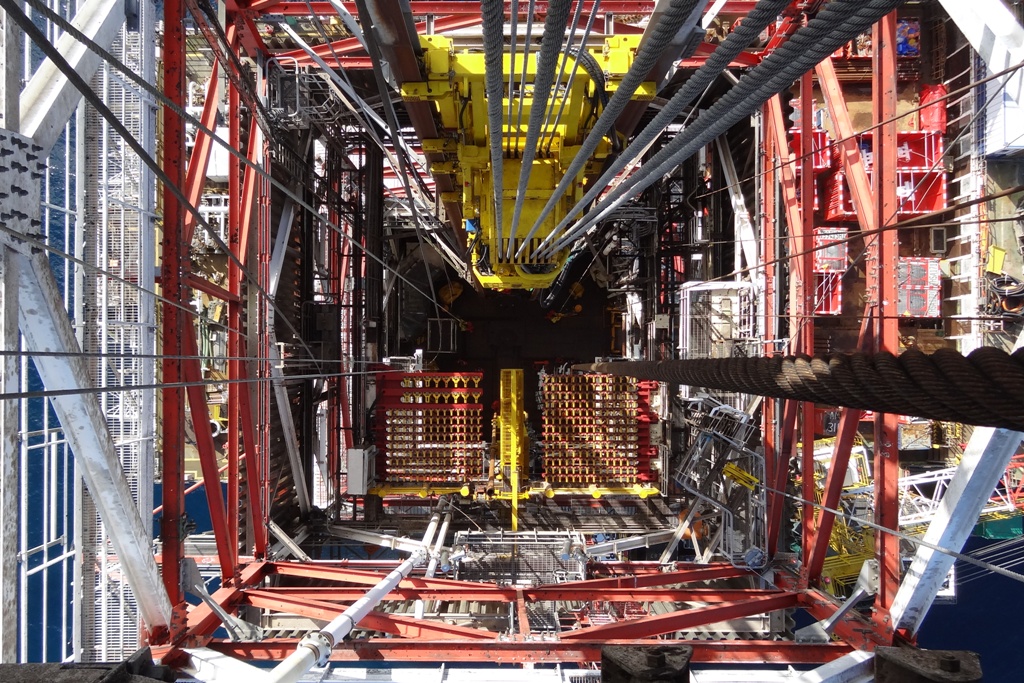

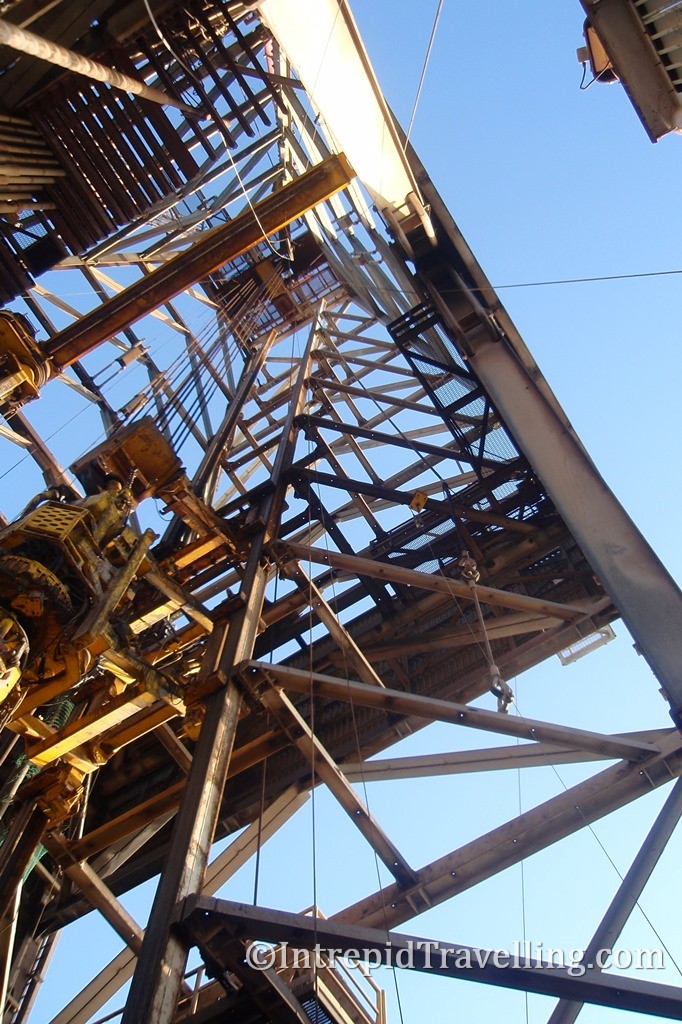

- Derrick – The derrick is the prominent steel tower that is used to hold the weight of the drilling tools, drill pipe, TDS, drill line and crown block.

- Pit room – Often located low in the rigs structure, the pit room is where the rigs fluids are stored that are involved in the drilling operations. There can be as few as four or over twenty tanks/pits used to segregate fluids. There is also a significant amount of pipework in this area to connect all the tanks.

- Mud – Drilling mud is a specially formulated, weighted fluid that is used during drilling operations to primarily control the wellbore pressures, lubricate the well, wellbore stability and clean the well.

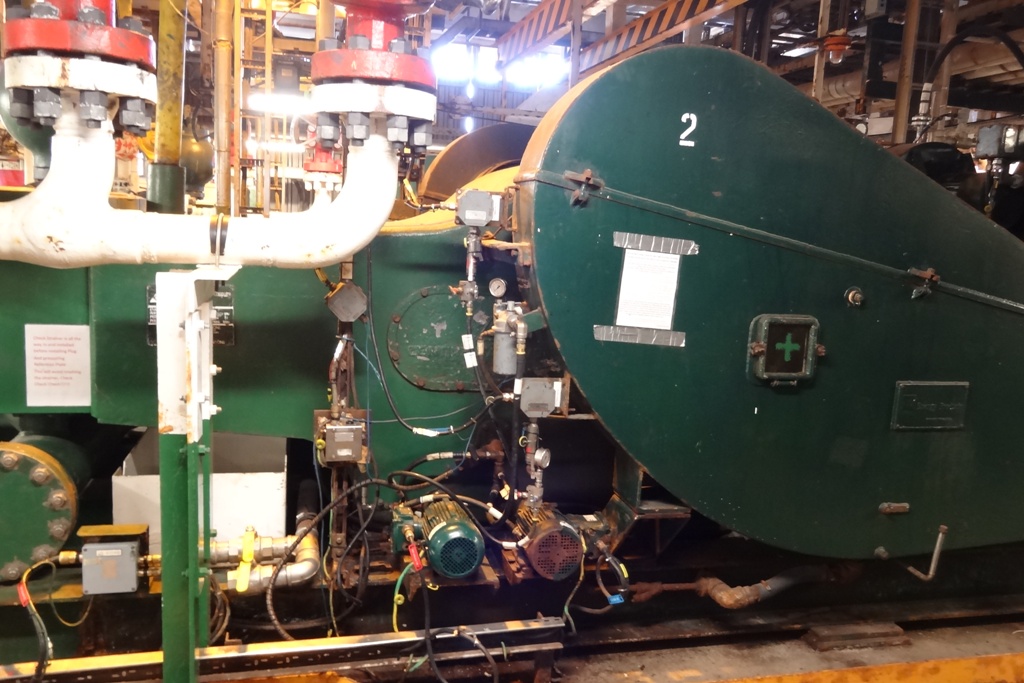

- Mud Pumps – On a typical jackup found in the North Sea, there will be three mud pumps used to pump fluid down the drill string to control wellbore pressures, lubricate the drill string and clean the well of the rock cuttings produced during drilling. These pumps commonly operate up to 6,000psi.

- Top Drive System (TDS) – Hangs on the drill line and is used to raise and lower the drilling tools as well as rotate the entire drill string (by hydraulic power) which can be over 25,000 feet long (7.6km) so imagine the torque required!

- Crown Block – A crown block is a fixed set of pulleys or sheaves through which the drill line (wire rope) is threaded and is directly above the traveling block.

- Drill line – The drill line is a braided wire rope that is threaded through the traveling block and crown block to enable the lowering and rasing of the TDS and drill string into and out of the wellbore.

- Draw works – Basically a very large hydraulic winch that is used to lift the drill string in and out of the well. The draw works maybe capable of lifting as much as 1,500,000 lbs.

- Pipe Racking System (PRS) – Is used in place of manual handling to move the drill pipe around the drill floor, mainly when tripping pipe in and out of the hole.

- Drill Pipe – Hollow steel pipe that typically come in 31 or 45feet lengths that screw together to make drill string.

- Blowout Preventers ( BOPs) – This would have to be my favourite piece of equipment on the rig. The BOPs are a stack of valves and heavy duty riser pipe used to ‘close the Well in’ if the Driller loses control of the Well and there’s a risk of a hydrocarbon release which could destroy the Rig. Some are rated to 20,000psi.

- Choke and Kill manifold – Can be used to manage returns from the Well via the BOP in an effort to manage pressures or volumes.

- Shale Shakers – Whilst drilling a well, rock cuttings will be washed to the surface by the drilling mud, the ‘shakers’ will vibrate the fluid and remove the solid particles from the mud before it returns to the pit room.

- Flowline – Returns from the well and shakers flows down this open trough back into the pit room where the fluid can be diverted in the various pits/tanks.

Sure it’s a job working on an isolated Rig in the middle of the North Sea, far from the simple pleasures of daily life. It’s not for everyone and most get tired of the isolation eventually and grow to hate the job as they miss their loved ones and life onshore. I’m sure I’ll tire of it too, but for the engineering minded it’s quite impressive to be involved with and a bit of an adventure if nothing else.